CM designs and manufactures complete tire shredding systems for making Tire-Derived Fuel (TDF)

CM Complete Turnkey Systems For Tire Recycling

CM Steel Liberation & Reclamation Systems

The CM Liberator and wire reclaim system is used in the production of rubber mulch and crumb rubber.

CM Granulation & Fiber Removal Systems

CM Granulators use V-Force knife technology to reduce material size and liberate fiber at high speeds.

CM Milling, Screening & Cleaning Systems

CM Shredders designs milling, screening, and cleaning systems for the final stage of tire recycling.

CM Shredding Systems For Industrial Applications

Oversized Item Minimization & Freight Expense Reduction

Oversized items and waste often present significant challenges in terms of management, cost, and environmental impact.

Industrial Liquid Separation & Shredding Systems

Safely and efficiently extract, isolate and size reduce components with our fully automated turnkey systems.

CM Uniform Particle Size Shredding & Fine Grind Systems

CM equipment designed to process a wide range of materials into smaller, uniform particles.

CM Zero Waste Reclaimed Wire Cleaning Systems

CM Zero Waste Wire Cleaning Systems allow processors to maximize the value of their reclaimed steel.

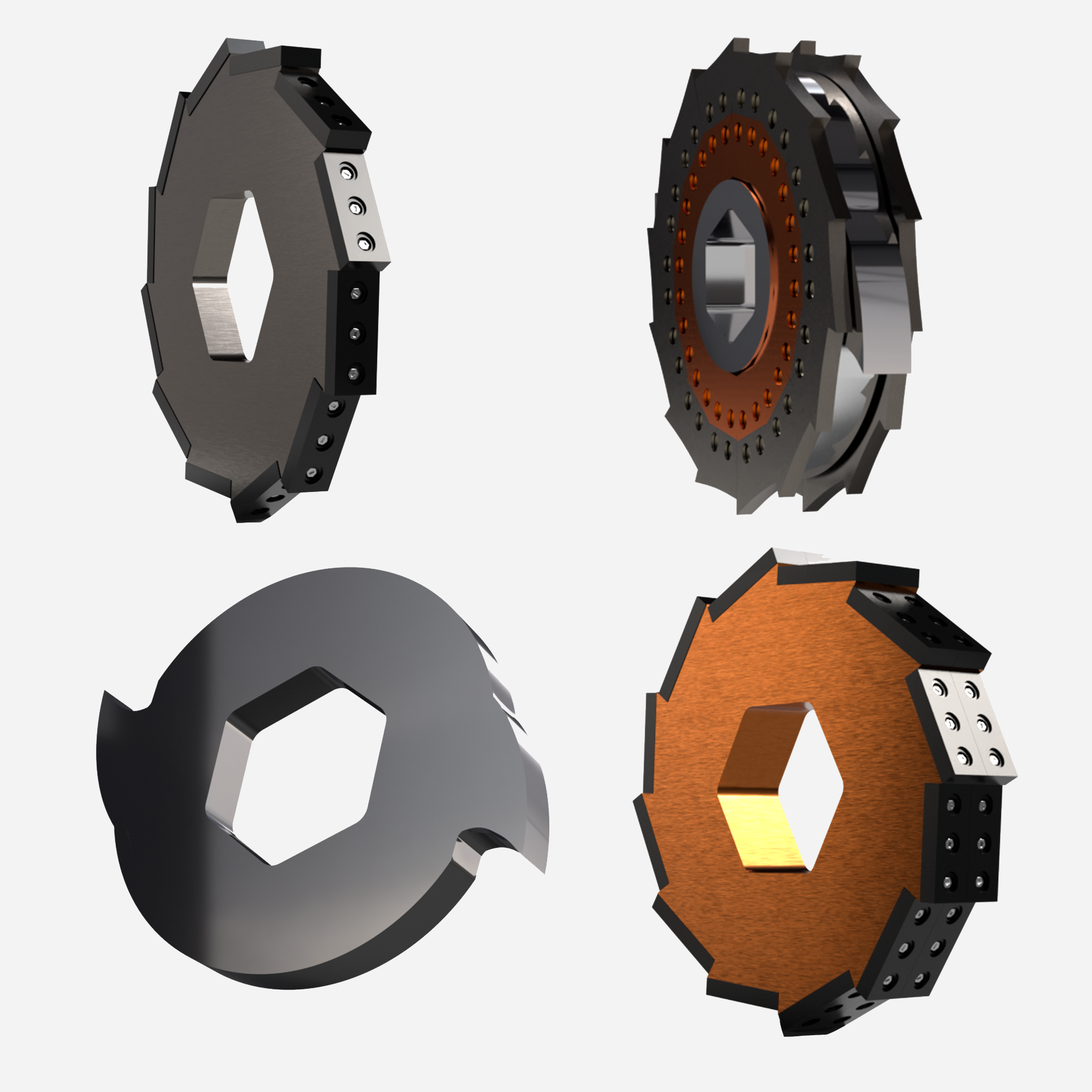

CM Shredders Patented Knife Systems

As an industrial shredder manufacturer, CM Shredders is proud to introduce a new line of general-purpose heavy-duty industrial recycling shredders with an array of new knife systems to improve and expand dual shaft shredders capabilities.

The best of both worlds! The New CM Hybrid line of industrial shredders allow operators to choose from standard hook and shear cutting chamber or CM’s patented quick replace resharpenable knives

- One piece or replaceable knife inserts for multiple applications

- Improved knife materials cut better and last longer

- Resharpenable/reusable knives for multiple uses

- Reduces knife cost and downtime

CM Shredders Latest News, Events & Resources

CM Shredders Commissions High-Capacity Tire-Derived Aggregate System in Tahiti, Transforming a Growing Waste Challenge into Sustainable Infrastructure

CM Shredders Commissions High-Capacity Tire-Derived Aggregate System in Tahiti, Transforming a Growing Waste Challenge into Sustainable Infrastructure Sarasota, Florida...

CM Shredders is known for designing and manufacturing some of the world’s most advanced industrial shredders and recycling systems. Headquartered for over 40 years in...

CM Shredders Installs High-Capacity Automated Tire Shredding System at SPSA Waste Solutions.

CM Shredders, a leading manufacturer of advanced industrial shredders and recycling systems, is proud to announce the installation of a new state-of-the-art, high...