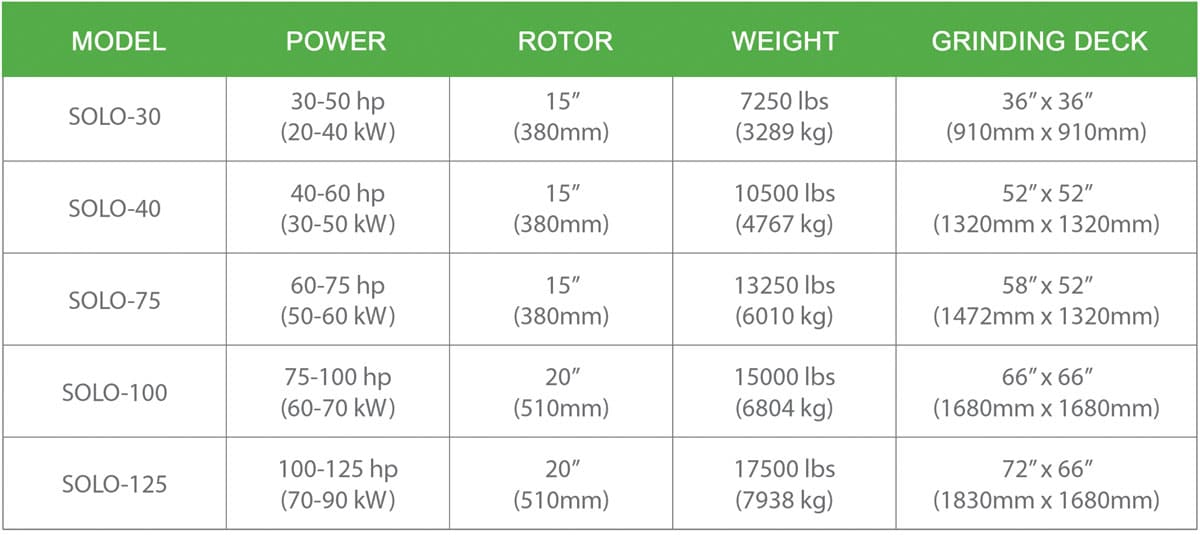

SOLO 30

Technologies – Featuring CM’s patented shredding technology, replaceable sizing screens, and a “Smart-Ram” system that automatically adjusts ram pressure. Yielding a longer tooling life, lower maintenance costs, and less downtime.

Features – Less power usage, minimal dust and reduced manpower requirements. The Solo features low noise levels, low RPMs and replaceable parts therefore making it a very efficient option for creating small particle sizes.

Screening – Interchangeable heavy-duty sizing screens are available multiple sizes. Screens are easily accessible for minimal down time providing many size options.

Knife Technologies – Four-way reversible tool steel cutting knives can be rotated 4 times resulting in lower operating costs.

Applications

Specifications

Complete Size Reduction Systems

The CM SOLO Series shredders have a minimal footprint and can work as a stand-alone machine or as a secondary machine to further reduce the output from a primary shredder.

Also for those applications requiring a complete fine grind system, the SOLO can be integrated together with the CM CrackerMill to produce a smaller, more specific target size.

The Solo is ruggedly engineered from the ground-up to be the toughest, most durable machines on the market. CM Shredders legendary build quality is evident from the heavy frame, bearings and shaft, to the electrical controls, and four-way reversible tool steel cutting knife technologies.

Features & Benefits

• Four-way reversible tool steel cutting knives can be rotated 4 times to lower operating costs.

• CM “Smart-Ram” system automatically adjusts ram pressure for steady feeding, maximum throughput and reduced manpower.

• Optimized, reduced power usage, minimal dust and low noise output.

• Heavy duty, replaceable sizing screens are available in many sizes and can be quickly changed out.

• High torque and low RPM cutting action provide greater cutting power.

• High Performance and over-sized gearboxes, bearings and fluid couplings.

• Separate control panel for complete versatility featuring programmable electronic system logic with digital read-out.

• Custom-built feed hoppers are to suit application.

• Several optional types of in-feed and discharge conveying equipment available.

• Optional downstream magnets to remove ferrous metal.

• Easily connects to a CM Milling Machine to create a fully integrated fine grind size reduction system.

Customer Service is Second to None – With CM “In Stock” Guarantee

We stock a complete line of replacement parts for all CM Tire Processing Equipment with shipping on standard parts within 24 hours.

Our dedicated Customer Service Team is available to fulfill your part orders via e-mail, telephone or fax. We ensure you will receive your package on time and at the lowest cost.

Field Service Technicians are available for your CM your equipment. Depending on location, our technicians can generally be on your site within 24 hours.