H-250 Hybrid Shredder

The CM H-250 is a heavy duty, high capacity hybrid shredder engineered for processors in landfills, municipal solid waste facilities, and tire recycling facilities. Features such as a wide feed opening, more knives, and 250 horsepower make this shredder the best solution for applications such as truck and OTR tires, wooden scraps and pallets, 55 gallon drums, and even solid waste. The H-250 is available with traditional knife configurations or CM “Multi-Stack” and “Double-Stack” patented replaceable knife inserts.

New Patented Knife Systems – Knife inserts that are made from through hardened tool steel that can easily be replaced and reground for multiple uses.

CM Secure Lock – Advanced knife group locking system to secure the knife group allowing the CM Hybrid shredder to hold the closest knife to knife tolerances for clean efficient cutting throughout the life of the knives.

Advanced Bearing Protection – Bearings are located outside of the work area and special bearing protectors are located between the work area and bearings eliminating contamination.

New Patented Knife Systems

Features & Benefits

Applications

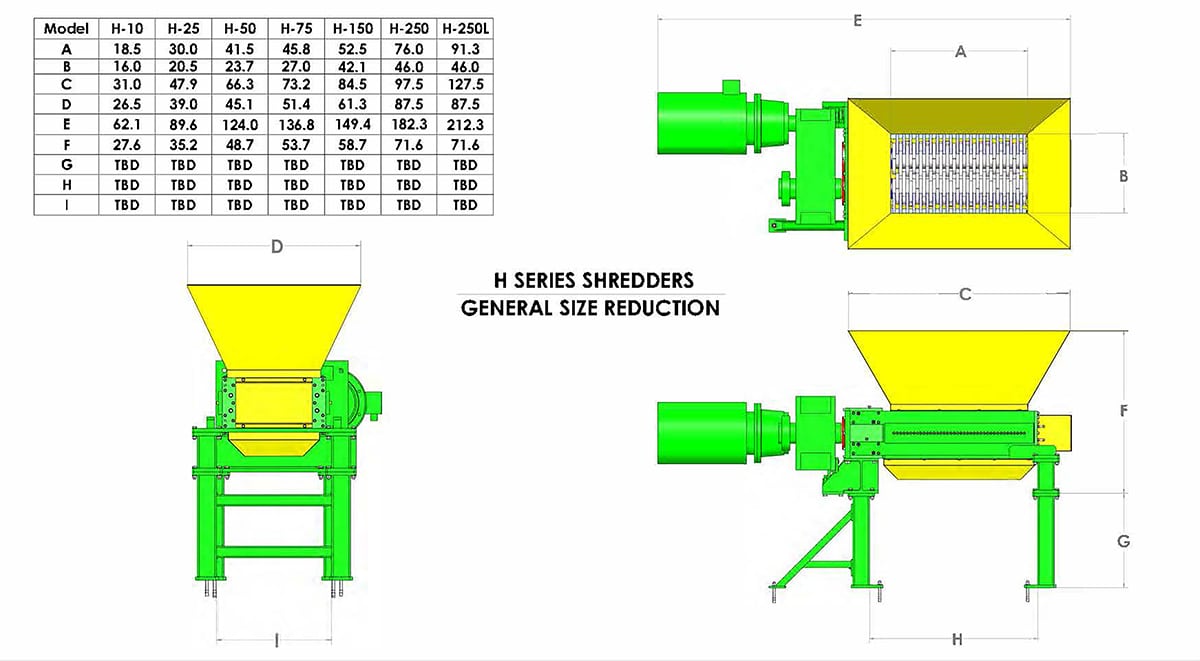

Specifications

Features & Benefits

• Multiple Knife Configurations

– CM Patented Replaceable Knife Inserts

– One Piece Traditional Knives

• Hexagonal Shafts

• Sealed Gear Box with Oil Splash Lubrication

• Tapered Roller Bearings

• Overload Protection with Auto Reverse & Automatic Shut Down

• PLC Controlled and Monitored

• Low Speed

• High Torque

• Low Wear

• Low Noise

• Low Dust

• Low Heat

• Low Vibration

CM Customer Service is Second to None – With In Stock Guarantee

We carry a complete line of replacement parts for all CM Shredders equipment with shipping on standard parts within 24 hours.

Our dedicated Customer Service Team is available to take your part orders via e-mail, telephone or fax. We use various freight carriers to ensure you will receive your package on time and at the lowest cost.

We also provide CM Field Service Technicians support if your equipment needs maintenance or repairs. Depending on location, our technicians can generally be on your site within 24 hours.